EFFECT

Ningbo Chunji Import And Export Trade Co.,Ltd Phone: 150 5806 6299 Email: yama@nbchunji.com Address: No.11, Moganshan Road, Xinqi Street, Beilun District, Ningbo City, Zhejiang

The car seat ventilation and heating system is an effective supplement to the car air conditioning system. It can adjust the temperature and humidity of the seat surface to meet the requirements of different drivers and passengers on the surface temperature of the seat in different seasons to the greatest extent, and helps the driver and occupant to maintain abundant energy and sober response.

The car seat ventilation and heating system is an effective supplement to the car air conditioning system. It can adjust the temperature and humidity of the seat surface to meet the requirements of different drivers and passengers on the surface temperature of the seat in different seasons to the greatest extent, and helps the driver and occupant to maintain abundant energy and sober response.

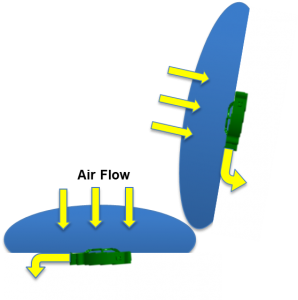

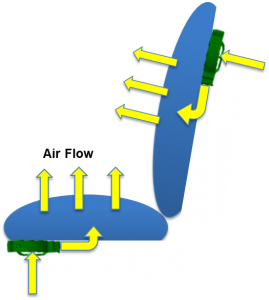

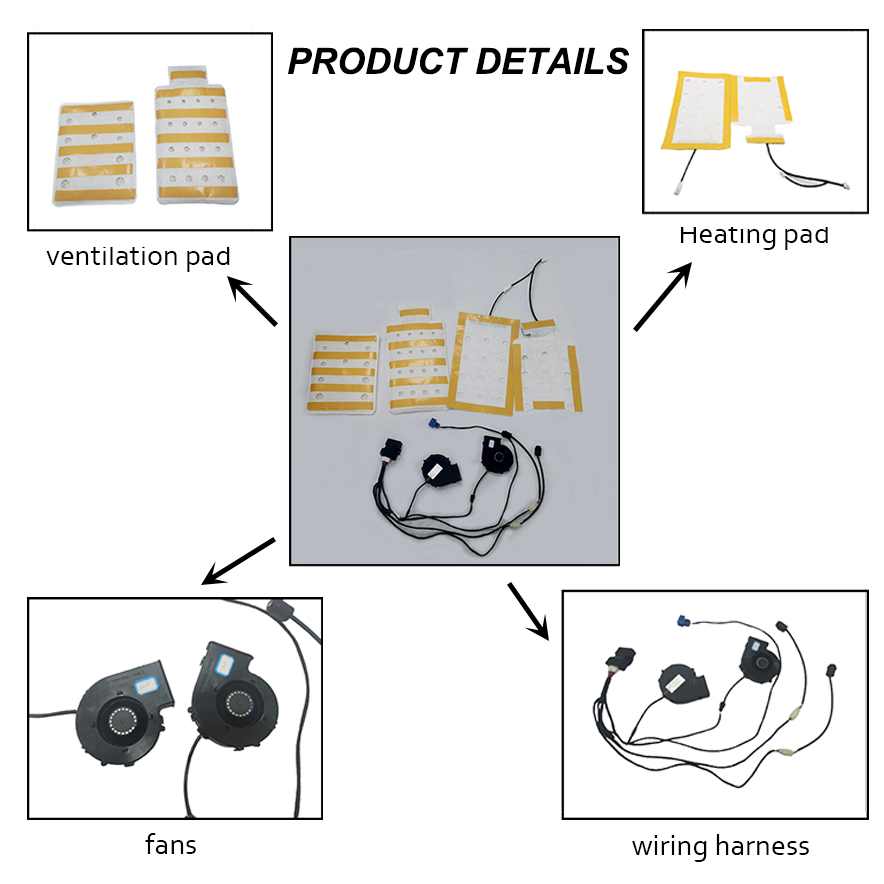

The car seat heating and ventilation system is mainly composed of air outlet and air suction devices, ventilation layers and special materials for anti-pressure, wind direction conversion devices and wind force size adjustment devices, which can form air outlet, air suction and heating on the surface of the seat and the back. It can quickly disperse the hot air, moisture and cold air on the seat surface, effectively improving the air circulation environment between the human body and the seat surface.

The car seat heating and ventilation system is mainly composed of air outlet and air suction devices, ventilation layers and special materials for anti-pressure, wind direction conversion devices and wind force size adjustment devices, which can form air outlet, air suction and heating on the surface of the seat and the back. It can quickly disperse the hot air, moisture and cold air on the seat surface, effectively improving the air circulation environment between the human body and the seat surface.

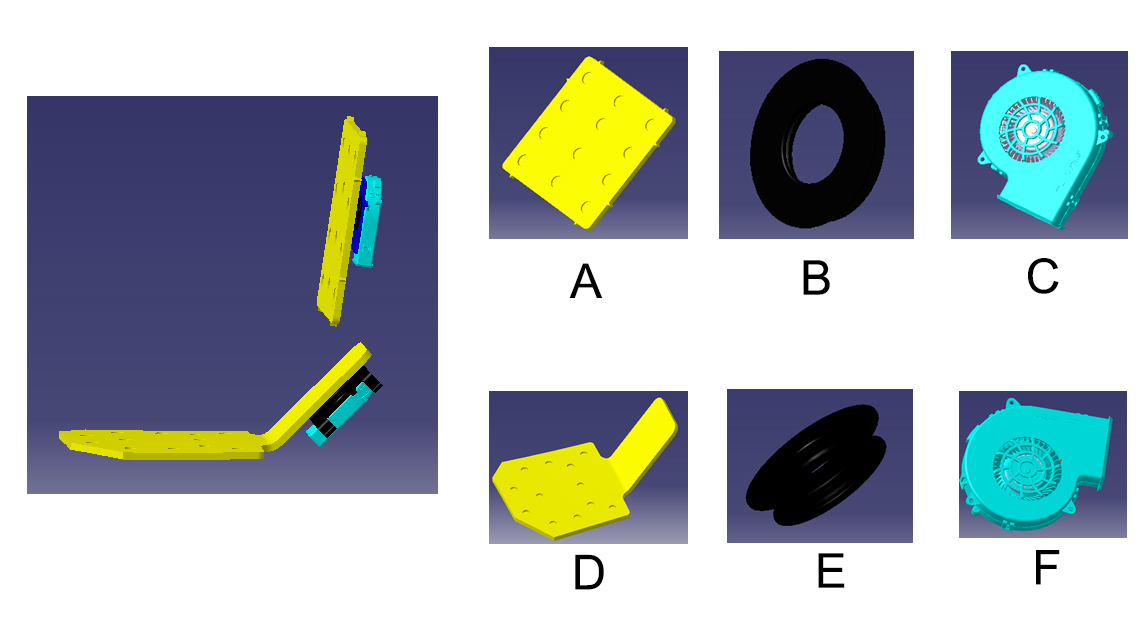

| Model | A | B | C | D | E | F |

| CJWA | Backrest ventilation pad | Cushion ventilation pad | The ventilation pipe | Fans | The ventilation pipe | Fans |

| item | value |

| Product | 2pcs of heating pads (1pc for backrest; 1pc for cushion) 2pcs of air networks |

| Function | air outlet, air suction and heating |

| Heating materials | white needle cotton and Teflon enameled wire |

| Ventilation materials | white laminating needle cotton and 3D mesh |

| Pad Size | backrest 441×210mm; cushion 307×230mm |

| Temperature controlled | 30 (lowest) to 70 (highest) |

| Low noise | 20-35dB |

| Type | CJWA |

| Color | Yellow |

| QE | Fatigue Durablity Test- 500 times | Electro- hydraulic servo fatigue test rig is for the car seat test equipment perormance testing |

| 2pcs of heating pads (1pc for backrest; 1pc for cushion) 2pcs of air networks | 10 thermocouples (the point 10 is room temperature)to real -time to measure of heating pad | |

| QA | Flammablity testing | Materials for Vehicle interiors Flammability Materia Requirements "US regulation 571.302 and acc .to Din 75 200 |

| High- Low Temperature test | Low Testing Temperature 20℃ (-4) ℉ | |

| FQC | High Votage shocking testing | 18 Votage against 8 min .100% checking |

| Power on testing | 100% Power on testing in 3 min per each one | |

| Resistance Test | Micro-Resistance Meter(0.01Ω) to check each pad |